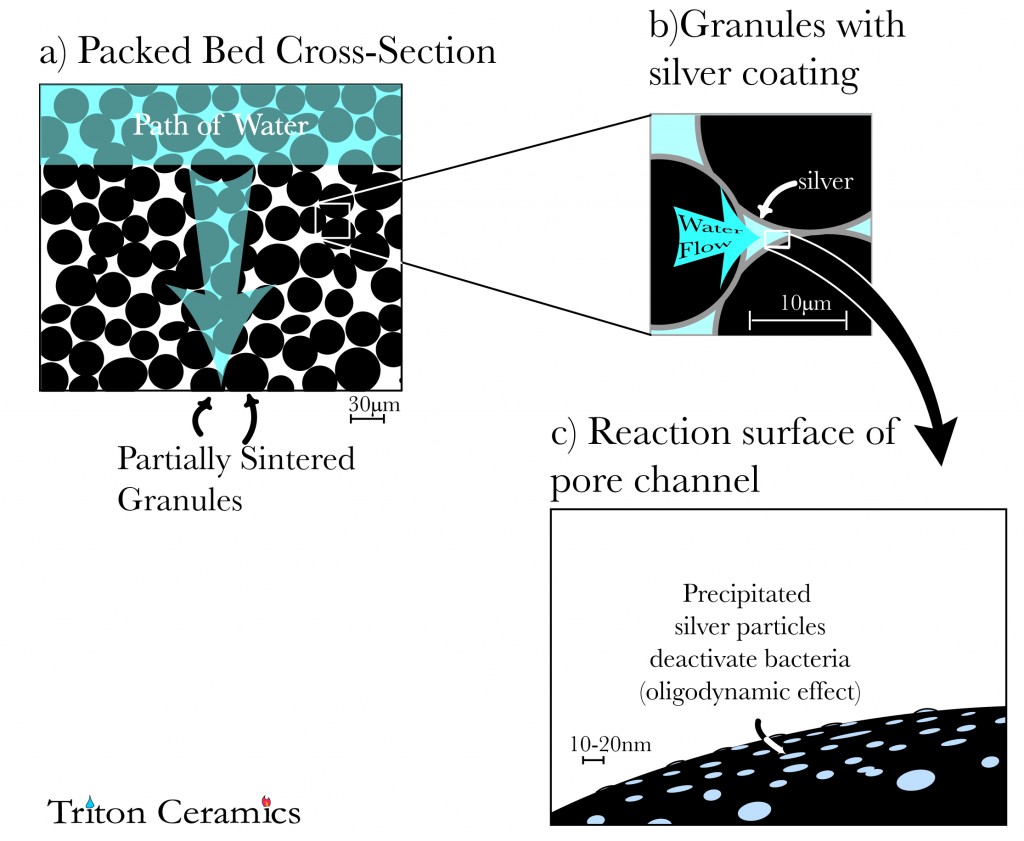

Triton Ceramics is working on silver-treated ceramic water purification technology. The devices employs a packed bed, which is an engineered structure of pores created by combining different size granules of ceramic. It’s kind of like very special sand packed together. The gaps between the granules create the network of pore channels. These pores act as a screen that blocks passage of organisms bigger than bacteria. A catalyst (silver) coats the pores and deactivates or kills bacteria as the water passes through. This action of silver deactivating bacteria is called an oligodynamic effect. This technique is excellent for producing drinkable water. The water is drinkable straight from the unit, meaning it is free from bacteria and larger disease-causing organisms. The technology is scalable, meaning it can be small enough to supply a single person, or large enough for water treatment plants supplying water for thousands. The technology shines when paired with other simple techniques, commonly called a water treatment package. The images below show a package design where the Triton Ceramics technology is used in conjunction with other types of water treatment. Also below is a cartoon showing an approximation of the microstructure inside the packed bed.

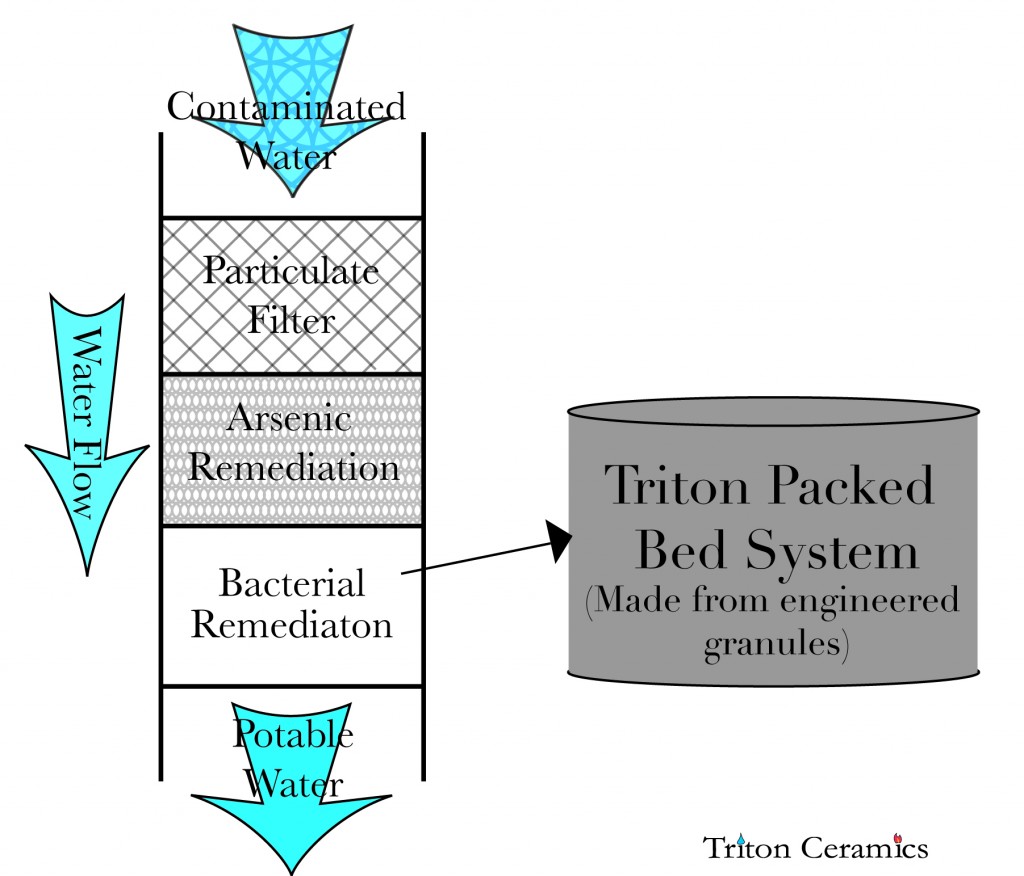

Cartoon of a water treatment setup. The example above has three parts working in harmony to deliver safe clean water. First water passes through a particulate filter that takes out things like sticks and dirt. Next is an element that addresses arsenic in the water, then finally the Triton Ceramics packed bed which takes care of bacteria and larger living organisms.

Cartoon representation of the Triton Ceramics technology, showing pore structure and silver at work.

We are using our knowledge of ceramic engineering, and pairing it with microbiologically sound techniques to produce new technology. Our technology is novel, but is steeped in the traditions of silver treated technologies that have come before. We are taking a new manufacturing approach to produce pores. This new technique gives us much greater control over pore size and distribution than traditional under-fired earthenware ceramic techniques. Greater control of pores means better control over safety, more consistent production, and better throughput. Better control of pores means a better device.

Additionally it is cheaper to produce, partially because the process requires much lower kiln temperatures. Lower kiln temperatures mean less fossil fuels used per filter.

Technology Advantages:

- reduced energy versus boiling

- no consumables such as chlorine required to produce drinking water

- no electricity required

- safe and effective

- cost effective compared to other drinking water techniques

- inexpensive to produce

- open source technology

What the technology is not intended for:

- virus protection

- chemical mitigation

Although our technology is not intended to remove viruses or chemicals in the water, it is however intended to be paired with other technologies where virus protection or chemical contamination are of concern. Where viruses and chemicals are prevalent, careful pairing with other types of water treatment can be a great option. Triton Ceramics is happy to be part of a larger water treatment community.

Triton Ceramics is committed to freely releasing the technology we produce to the public. We believe that this strengthens the entire field of producers making drinking water devices that incorporate silver.