Grow Baby!

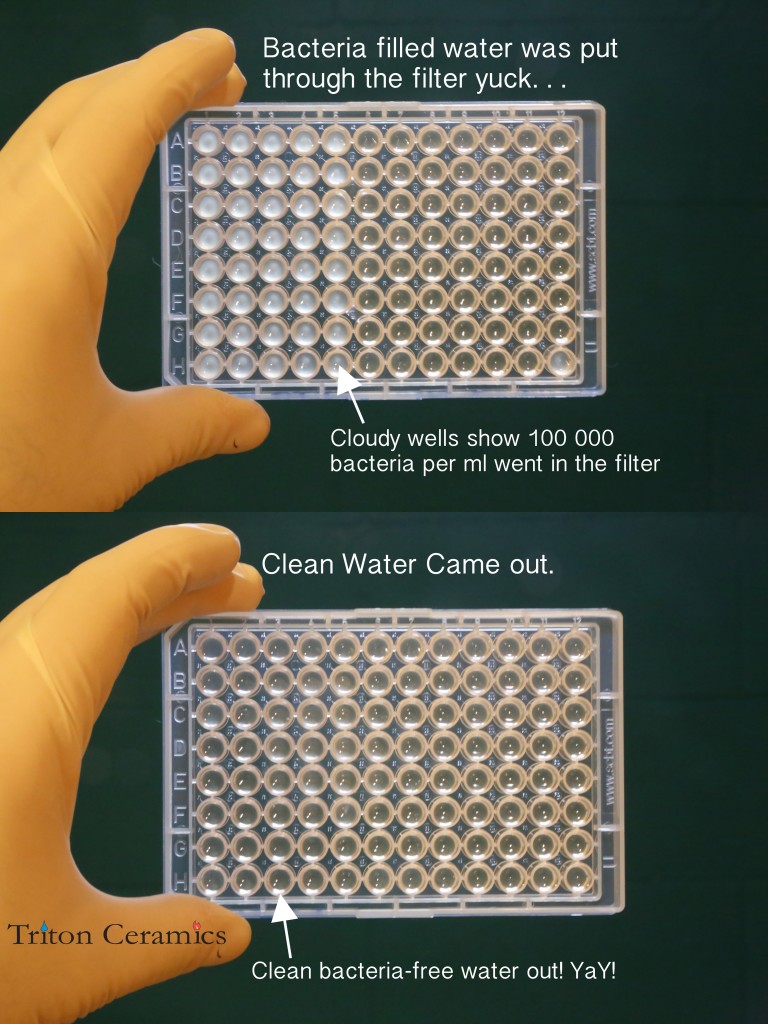

Triton Ceramics has reached a critical point in its development and is now ready to grow and expand. It has been four and a half years since I returned from Indonesia, to Alfred. I have accomplished much in that time! For example it has become clear that the technology will meet the stringent quality standards that I have been working towards since the beginning. Many samples in the lab are hitting the marks. The silver kills bacteria. The business plan is together (and I can send you a copy if you’d like to see it). I have developed dozens of relationships with advisors in the fields of materials science, microbiology, manufacturing, business, finance, and the law. I’ve even made NGO connections who are interested in purchasing the final product. I have been going slowly and learning as much as I can about all aspects of the field. All of this careful slow time over the last four and a half years has put Triton in an absolutely excellent position for the next steps.

So the silver is working, but to get consistent predictable results I need to ramp up the pace.

I need to free more of my time to work on Triton Ceramics. The time I am able to put into water filters after sustaining myself through my paid employment (school bus driving) is not enough. Working on Triton Ceramics while working another job has allowed me to do a huge amount of work with very little money, but I can dedicate myself to accelerated progress if I can draw a living stipend.

In addition to spending more of my own time on water filters, I also need to hire people with expertise that I do not have. Specifically, I need to hire a microbiologist. Since September of 2015 I have realized that my microbiology lab was not up to the task of repeatably testing the filters. By September 2016 I was able to get the lab in order, and that was with the help of Cheyanne Smith (summer Intern), John Buckwalter (lab assistant), and almost weekly visits from Mary Merner (consultant). An expert in the field would have taken only 1-2 months to do the same amount of work. I love learning new things, and learning more about microbiology testing will be valuable in this line of work, but hiring an expert is essential to make the business function.

By not charging for my time, and by carefully looking for inexpensive ways to do things, I have progressed to this point having spent very little cash. The value built so far has come without debt and with many lessons learned. It was wise to operate this way because it enabled me to challenge myself to find ways to do things that do not require cash. It has been an exercise in slow wise progress, but it is time to pick up the pace carefully and diligently.

My plan for the next step, which is to get the lab results consistent and a prototype developed, is to hire a microbiologist and a ceramic engineer. In addition, I want to dedicate myself to working full time on the water filters. I will use this time to ready my team for production.

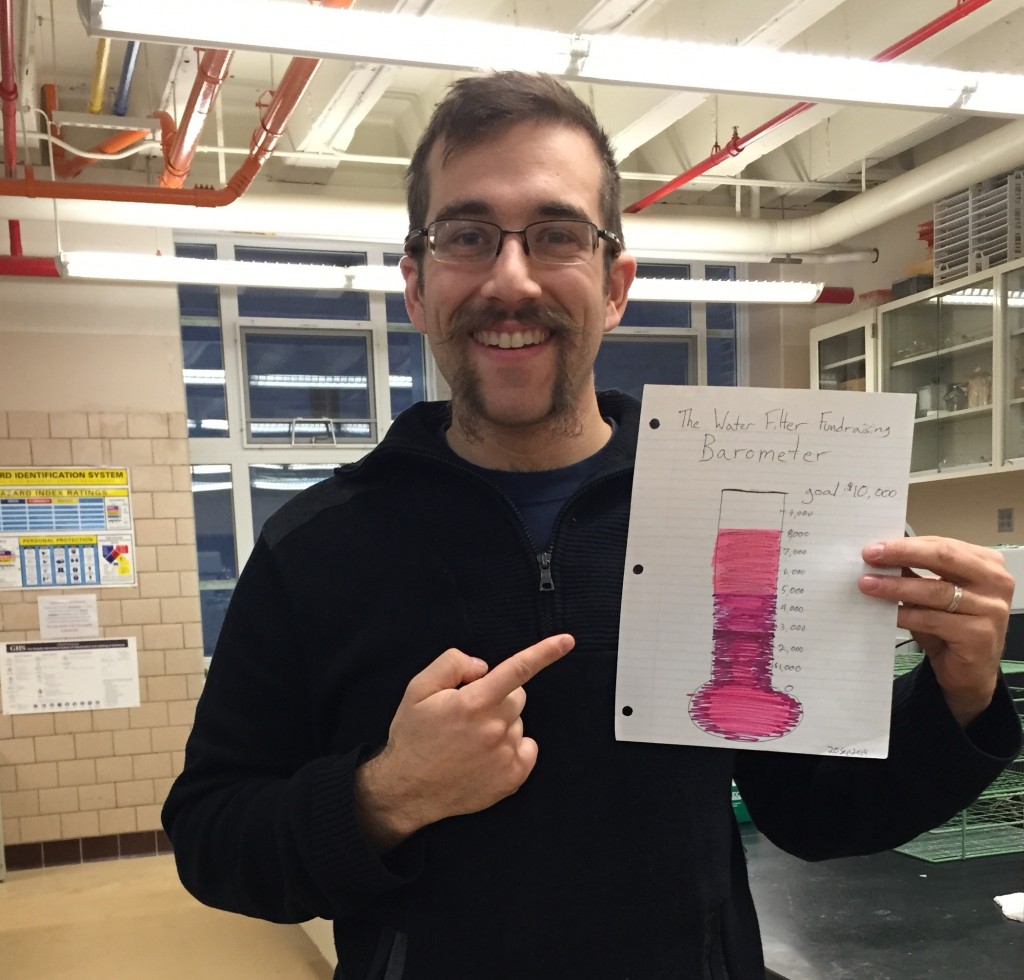

I know YOU are interested in supporting the next steps, and we could use your help in the form of a loan to Triton Ceramics. This is a great opportunity to invest your money behind a positive technology poised to make a difference in the world. I hope to raise a significant portion of the money needed for the next year from our Triton Ceramics community through this loan. I am also looking for government grants to pay for another large chunk of this coming stage of the research. I have come to you first because the money from this community is a not merely a funding source, but a clear affirmation of the water filter work. Your support will keep me grounded. We are still in the early stages but we have a great shot at this. Be warned, there is risk involved. Any investment carries risk. I plan on having 20 or more lenders in this round of funding. There is not a nobler cause than helping people keep themselves healthy with pure drinking water.

If you are interested in finding more about this opportunity and the specifics of the loan, lets talk. You can contact me by email(TritonCeramics@gmail.com) or give me a call: 585.808.9172 I look forward to talking with you!

-Nick